The project, called Advanced Heat Exchange Devices (AHEAD), kicked off this summer and aims to revolutionize thermal control systems – critical components of a number of high-performance devices like satellites and space rockets. Most thermal control systems in use today are heavy, and bulky and require a myriad of connection cables. With AHEAD, the goal is to develop systems that are compact, less expensive and wireless, allowing for real-time data collection and improved efficiency.

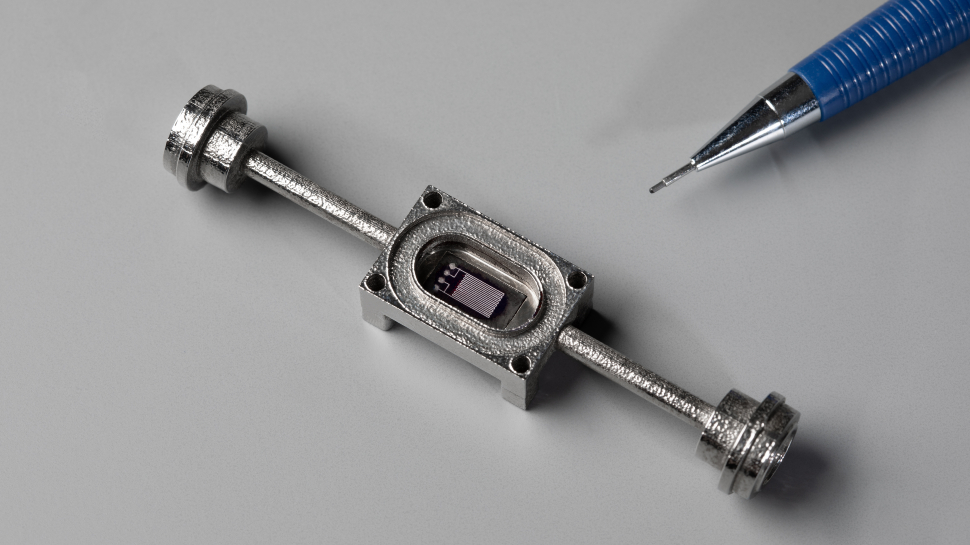

The project consortium, which consists of six partner organizations, intends to develop a new kind of 3D-printed pipe with temperature sensors and heating elements embedded in the pipe’s inner surface. The system will also include an energy recovery device to power the embedded electronics and enable automatic, wireless data transfer.

“Broadly speaking, we aim to develop technology bricks that can be used to integrate electronic components like cables, connectors and sensors into many different kinds of 3D-printed objects. The ability to embed sensors into process equipment will be an important feature of Industry 4.0. The data collected by these sensors can be used to feed artificial intelligence algorithms for process control, process optimization and predictive maintenance,” says Hervé Saudan, coordinator of the AHEAD project

Read the full story at the Centre Suisse d’Electronique et de Microtechnique (CSEM) website here.

More information about the AHEAD project here.