Glass is one of the most important materials of the 21st century, and despite millennia of use, its processing techniques have remained largely unchanged for decades. The Glass2Mass project is about making small parts from fused silica glass using two-photon lithography and UV Nanoimprint Lithography (UV-NIL). Moreover, Glassomer has invented a worldwide unique process to shape fused silica glass at near room temperature.

This project is coordinated by Glassomer, a spin-off of Freiburg University, in partnership with Nanoscribe, one of the market leaders in the field of high-resolution 3D printing by direct laser writing, EV Group, a company in the field of nanoimprint lithography instrumentation, and OSRAM, a company in the field of projection, optics, and illumination.

Get to know more about this project through an interview with Dorothea Helmer, coordinator of Glass2Mass.

What is your personal and career journey so far?

I studied chemistry at the Karlsruher Institut für Technologie (KIT) in Karlsruhe, and I went on to do my postdoc at the University of Freiberg, which is where I met my co-founders Frederik Kotz-Helmer and Bastian E. Rapp, who had invented the process of glassmaking at low temperatures. And that’s when we founded Glassomer and also developed the technology which brings us where we are today.

What is the project about? And which partners are involved?

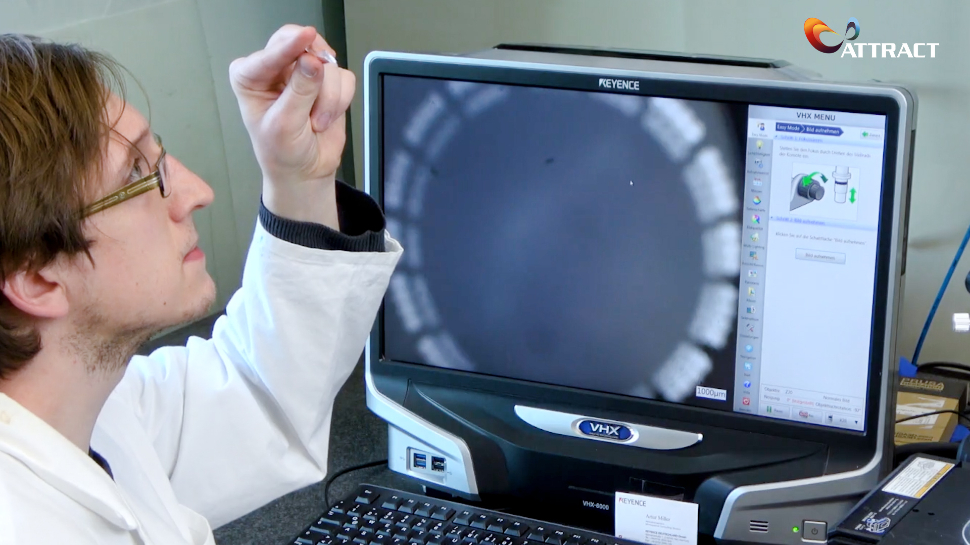

The project is about making really small parts from fused silica glass, using two-photon lithography and UV Nanoimprint Lithography (UV-NIL). We, at Glassomer, have invented a worldwide unique process where we can shape fused silica glass at near room temperature. The consortium consists of us Glassomer, we are the material experts and EVG and Nanoscribe who are the experts on making really, really small parts. And then we also have OSRAM on the team, they advise us on the markets and on the design of the optical parts.

What challenges have you faced so far?

Research and Development is always a challenge because in research 95% of the things that you do, do not give you the answer that you were looking for, they sometimes even raise more questions, but luckily on this project, we are working with experts who have known their processes for many years. So, up until now, we were lucky enough to solve the problems and challenges that we have been facing.

How would you explain the potential implications of this breakthrough to a non-scientific audience?

You need light in many of your daily used objects like for instance, your smartphone, your computer, your car, for instance. And all of these have light sources and with our technology, we can more efficiently harvest light and guide it in certain directions. Also, in case you didn’t know, your smartphone makes different pictures depending on the temperature of the device. That is just because the lenses are made from plastics, and they expand, and they shrink upon temperature changes. That’s why it would be really nice to have a material that withstands all of these chemical and thermal and mechanical challenges. That is fused silica glass. And that is what Glass2Mass is about.

How do you think society will benefit from this project?

Society will benefit in two ways from the project: the first one is in the products that we can generate. So, if you think about it, you need light in all the devices that you are using on your smartphone, in your car, in your computer, and the internet comes through light, for instance. And when we do our job well, then we can actually make, for instance, the internet connections faster. And we can also make sure that your smartphone takes the same images at whatever temperature. The second advantage is that our technology is energy-saving and resource-saving because we make our glass at 700 degrees below the melting point of the glass which saves us a lot of energy and resources.

For more information

Visit the Glass2Mass project site.